Railway Painting & Maintenance Solution

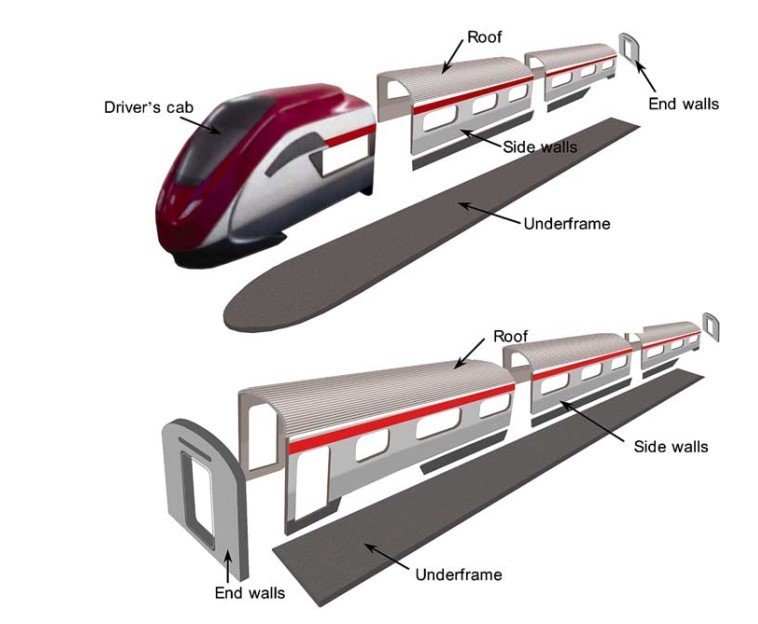

Carbody/Boggy Surface Preparation and System Coat Painting Polishing Work

Surface preparation and painting are essential for maintaining and enhancing the appearance and durability of carbody or boggy surfaces. The process begins with thorough cleaning to remove dirt, grease, and contaminants. This is followed by sanding to eliminate old paint, rust, and imperfections, creating a smooth surface for better paint adhesion. Rust treatment and body filler application ensure any damage is repaired and the surface is perfectly leveled.

Once the surface is prepped, a primer coat is applied to provide a solid foundation and enhance paint adhesion. After the primer cures, the base coat is applied, offering the primary color and visual appeal. A clear coat follows, adding gloss and protection against UV rays, chemicals, and minor abrasions. Each layer requires proper drying and curing to ensure durability.

The finishing touches involve wet sanding to remove any minor imperfections, followed by buffing and polishing to achieve a high-gloss, mirror-like finish. Finally, a protective wax layer can be applied for added shine and protection. This meticulous process ensures that carbody or boggy surfaces not only look visually appealing but are also well-protected against environmental factors, extending their lifespan and maintaining their appearance.

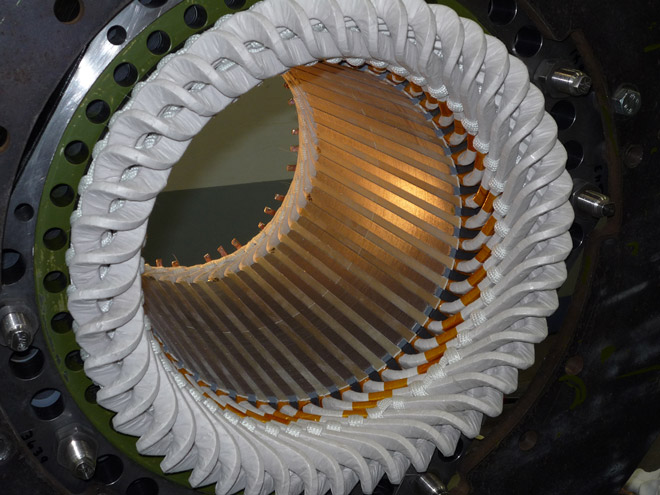

Traction Motor Painting Work

Traction motor painting is crucial for protecting these essential components in railways, electric vehicles, and industrial machinery from environmental damage and wear. The process begins with meticulous cleaning using industrial-grade degreasers and high-pressure washing to remove grease, oil, and dirt. Abrasive blasting, such as sandblasting, follows to strip old paint and rust while roughening the surface for better paint adhesion.

Sensitive parts like electrical connections and bearings are masked to prevent paint contamination. After blasting, the motor surface is inspected and any imperfections are repaired using fillers, which are then sanded smooth. An epoxy primer is applied to enhance adhesion and provide corrosion resistance, with multiple thin coats ensuring even coverage.

The base coat is then applied, providing the primary color and additional protection. Depending on the motor’s environment, specialized coatings such as anti-corrosive or heat-resistant paints may be used. Each layer undergoes proper drying and curing, either through air drying or controlled heating.

The final steps involve a thorough inspection for defects, followed by the application of a clear coat or protective varnish for added gloss and protection. The masking is carefully removed, and any residual adhesive is cleaned off, resulting in a durable, professional finish that enhances both the appearance and longevity of the traction motor.